Picture from SDSC Website

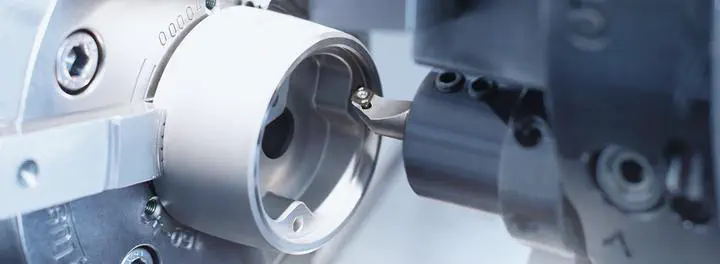

Picture from SDSC WebsiteWEFA Singen GmbH is part of the WEFA Group. The company specialises in the production of aluminium extrusion dies. In addition to leading aluminium groups, its customers include innovative medium-sized extrusion plants. Today, the company has five locations worldwide and employs over 250 people

The data received from WEFA Singen came mainly from the extrusion press production line. It included the description of the target product, the raw material used and the mould production process data. In total, the data comprised a physical volume of 1.3 GB and contained more than 200 individual characteristics and 20,000 different entries. In addition, the company provided a detailed description of the feature priorities as well as a description of the method used to generate the data set. The latter played an important role in the pre-processing of the data set.

The project focussed on three main topics: Data pre-processing, regularisation and visualisation. Data pre-processing took up most of the processing time and was the core component of the analysis. Based on these findings, the experts had to find an efficient compromise between the accuracy of the developed model and the best possible visualisation method for the model results. The adjusting screw for the compromise was the regularisation step. The SDSC-BW team was able to extract suitable rules that allowed WEFA Singen to extract further rules in a targeted manner using the selected visualisation method and application of the existing domain knowledge.

In order to be able to optimise quality, the experts determined the influencing factors responsible for product quality. To do this, they used modern algorithms and trained a model with which they were able to identify hidden patterns in the underlying data. They handed over the visualisation of the trained model to WEFA Singen so that the company could identify further suitable patterns using internal domain knowledge.

The SDSC-BW team trained a model that improves the existing assessment method and thus proves that the given factors can influence the target attribute. The experts identified suitable visualisation methods and presented the created model. The SDSC-BW scientists used the project to show that machine learning makes it possible to analyse the factors that influence product quality.